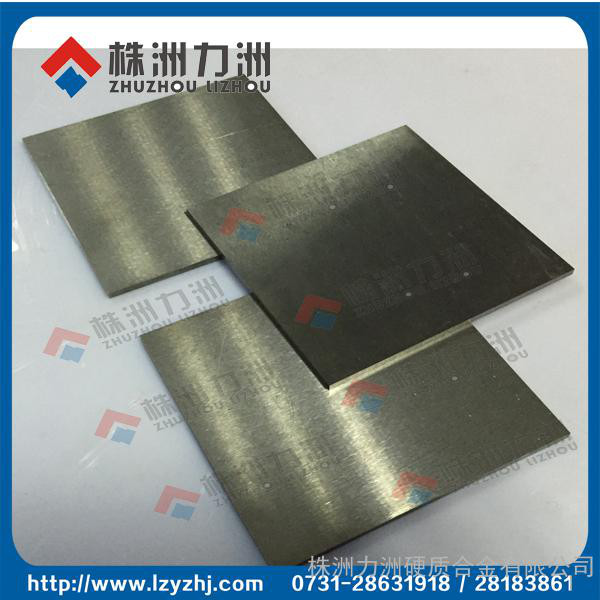

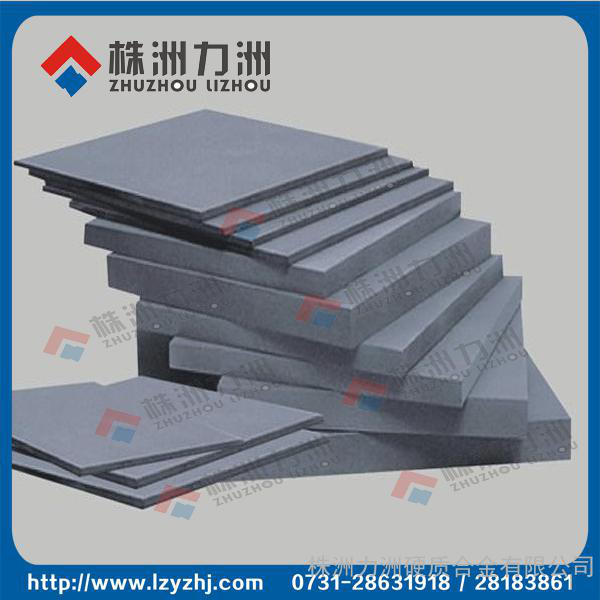

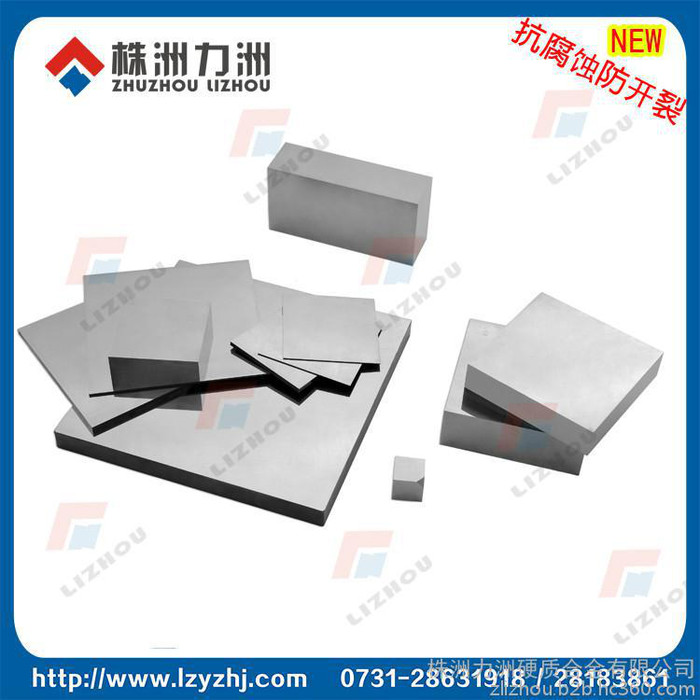

| 品牌 | 力洲 |

|---|---|

| 主要金属含量 | 碳化钨 |

| 产地 | 湖南株洲 |

| 杂质含量 | 0.001 |

| 粒度 | 80 |

| 牌号 | YG8 |

本公司生产的板块是制作耐高温零件、耐磨零件、防屏蔽零件、耐腐蚀零件、耐冲挤压零件的**材料,我公司生产设备先进,质量保证,欢迎咨询洽谈。我公司有以下设备:

喷雾塔(Spraying and drying machine)

混合料制备字全密封的环境下采用高纯氮气保护,有效的减少制备过程中原料的增氧的可能,并能有效的保护原料的纯度,防止物料的脏化。

With high purity nitrigen protection in a fully enclosed environment, the mixture oxygen are effectively reduced, material purity are effectively guaranteed and the material dirty are prevented.

冷等静压制(CIP)

采用2000Mpa 等精压机,有效的杜绝压制产生的缺陷,使毛坯压制密度更均匀,从而为硬质合金的生产提供了良好的保证。

Bring in the 2000Mpa isostatic pressing machine, which put the end to the defects effectively and make the carbide blank density uniform , it also guarantee the good quality for tungsten carbide production.

全自动成型压机(TPA)

全自动电脑操控,保证称料控制的**型,从而保证批量产品的单重的统一性。由于上下双向受压,从而也保证毛坯产品的致密性。

The production processing operated by computer control system, not only the weight of the powder was taken but also the piece weight of the products were well control and guarantee. In additional, the good quality of the carbide blank with high density due to it’s great pressure formed by up and down together.

低压烧结(HIP)

**大压力烧结可以达到400公斤以内,是合金机体内部的空隙得以有效的消除,从而得到致密化良好的高硬度、高强度的合金毛坯。先进的控温系统可有效的减少硬质合金产品出现质量问题的波动。

The maximum sintering pressure can reach 400kg, which eliminated the internal void of the tungsten carbide and get the high hardness and high strength.